Dry Ice Blasting

Dry ice blasting is a non-abrasive, non-conductive, chemical-free cleaning method that leaves no residue. It’s ideal for sensitive, technical, and restoration applications across many industries.

Automotive & Transportation

- Engine compartments (removes grease and oil without damage)

- Undercarriages and suspensions

- Brake and fuel system components

- Electrical components and sensors

- Vehicle interiors (mold, smoke, odor)

- Classic car restoration (paint stripping without warping)

- Boat hulls and engines (algae, barnacles, grime)

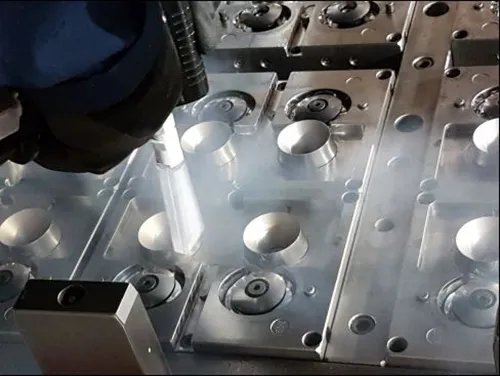

Industrial & Manufacturing

- Mold cavities (rubber, plastic, composite)

- Production equipment (grease, oil, dust)

- Conveyors and rollers

- Hydraulic systems

- Motors, pumps, gearboxes

- Control panels and circuitry

- Printing presses and equipment

- Weld fixtures and tooling

- Electrical cabinets (safe on live equipment)

Food & Beverage

- Ovens and grills

- Mixers and blenders

- Food conveyors

- Packaging lines

- Bottling machines

- Industrial refrigeration coils

- Clean rooms and food-safe environments (no secondary waste)

Electrical & Electronics

- Circuit boards

- Control panels

- Electric motors

- Generators

- Switchgears and substations

- Robotic arms and sensors

Wood & Building Materials

- Fire and smoke damage on wood framing

- Soot and charring removal from beams

- Paint and stain stripping

- Mold remediation (attics, basements, crawl spaces)

- Log homes (restoration, staining prep)

Facilities & Maintenance

- HVAC systems and coils

- Elevators and escalators

- Lighting fixtures

- Walls, ceilings, and structural steel

- Mechanical rooms

- Parking garages (oil, gum, grime)

Historic Preservation & Restoration

- Antique furniture and fixtures

- Fire-damaged buildings (brick, wood, metal)

- Statues and sculptures

- Artifacts (delicate cleaning without abrasives)

Medical & Pharmaceutical

- Stainless steel surfaces

- Sterile processing areas

- Conveyor systems

- Production and packaging equipment

Aerospace

- Composite molds

- Aircraft interiors and exteriors

- Avionics and electronic systems

- Tooling and fixtures

Energy & Utilities

- Turbines and generators

- Wind turbine blades

- Solar panels (non-abrasive)

- Power substations

- Transformers

Agriculture

- Tractors and combines

- Dairy and milking machines

- Conveyors and grain handling systems

- Barns and poultry houses (sanitize without water)

Residential & General Cleaning

- Mold remediation (walls, attics, basements)

- Graffiti removal (brick, concrete, metal)

- Smoke damage and odor

- Decks and fences (paint/stain prep)

- Pool equipment and tiles

- Garage floors and workbenches

Ready to get started?

Contact us for a free quote or to discuss your project. We respond quickly!

Project Gallery

Why Dry Ice Blasting?

Dry ice blasting, also known as CO₂ cleaning or cryogenic cleaning, is gaining serious traction across multiple industries thanks to its eco-friendly cleaning methods, non-abrasive nature, and deep-cleaning capability. This green cleaning technology uses dry ice pellets propelled by compressed air to remove contaminants from surfaces through a sublimation cleaning process-where the solid CO₂ turns directly into gas, leaving behind no secondary waste.

In the automotive industry, dry ice blasting excels at engine and undercarriage cleaning, removing grease, oil, and grime without harming parts or leaving residues. Unlike traditional surface preparation methods, it cleans deeply without dismantling components, saving time and labor.

In the food and beverage sector, where hygiene is paramount, dry ice blasting provides sanitation without chemicals. It’s ideal for cleaning food processing equipment, conveyors, and packaging lines. Since it’s a non-toxic and non-conductive method, there’s no need for water or solvents-ensuring compliance with strict FDA standards.

The restoration industry heavily relies on this technology for mold remediation and fire damage cleanup. It gently strips away mold, soot, and char from wood, brick, and metal without spreading spores or damaging the substrate. The dry ice blasting process is especially useful in historic building restoration where preservation matters.

In manufacturing, dry ice blasting is a top-tier solution for equipment maintenance and cleaning. It can remove buildup from hydraulic presses, extruders, and electrical panels without halting production. The dry ice blasting benefits in this sector include increased uptime, reduced wear, and a safer work environment.

Always ensure operators are trained in dry ice blasting safety and using certified dry ice blasting equipment for optimal results.

Ready to explore these industrial cleaning solutions? Dry ice blasting might be the breakthrough your business needs!